DESIGN

Equipped with modern facilities to design and a highly qualified team, our Project Department and their divisions will offer you the most adequate solution to any speed and/or power transmission problem, from the simplest gearbox to the most technologically complete group.

The Engineering group offers the best state-of-the-art solutions to companies in different sectors, like Steel, Petrochemical, Public Works, Mining, Power, Capital Equipment, etc.

The Technical Office, together with the CAE/CAD/CAM unit and the Methods section, develops and projects according to the most modern technologies and the latest international standards, optimising component and group design through analysing and simulating their mechanical, thermal, etc. behaviour.

SADIRET

Design Programme

The SADIRET (Spanish acronym for “Design Assistance System for TANDEM Gearboxes”) application is devised to facilitate the design work of TANDEM gearboxes made by ETC-RALPE.

The TANDEM-type mechanisms are standardised in their main features, maintaining the parameters defined in the catalogue, while there are other parameters, especially those related to the characterisation and sizing of their kinematic chain, which are designed on a case by case basis depending on the working environment, the specifications of the machine they drive or the particular customer needs.

From the technical specifications requested by a client, the SADIRET application enables the automation and packaging in a single block the calculation tasks of the gearbox components and the production of plans and reports, minimising this way the design time of such gearboxes.

The SADIRET application is formed by two key components:

- The application user interface, which enable the access to its functionality

- The ORACLE database, that stores all resulting data from calculation and references to the CAD plans produced

The SADIRET application covers all the design phases of a TANDEM gearbox

The SADIRET application is formed by the following functional modules:

Data Input Module

It is the starting point of the application, since it is the module where the gearbox at hand data is input from. The input data include general information as well as precise data to carry out the subsequent calculations. It is in this module where the customer particular technical specifications are introduced.

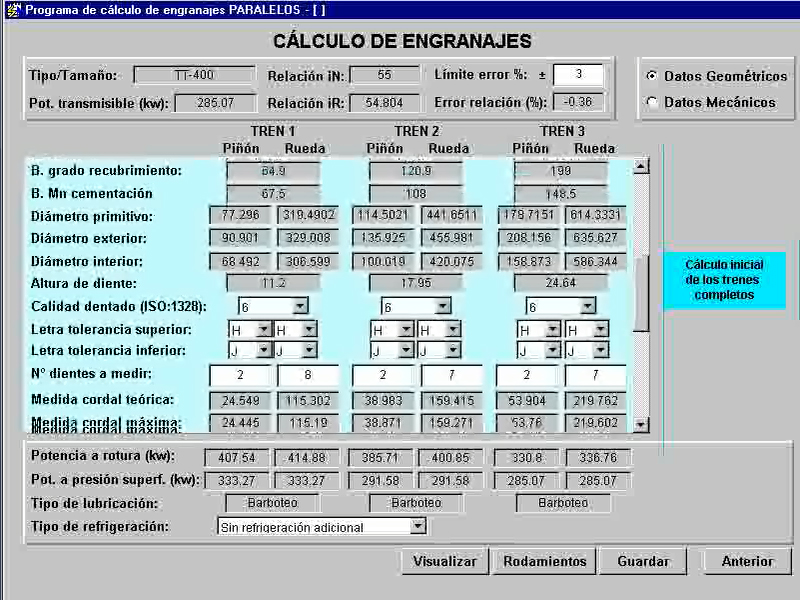

Parallel and Bevel Gear Calculation Module

From the input data, this module will carry out the geometrical and mechanical calculations of the gearbox and the results will be stored in the database.

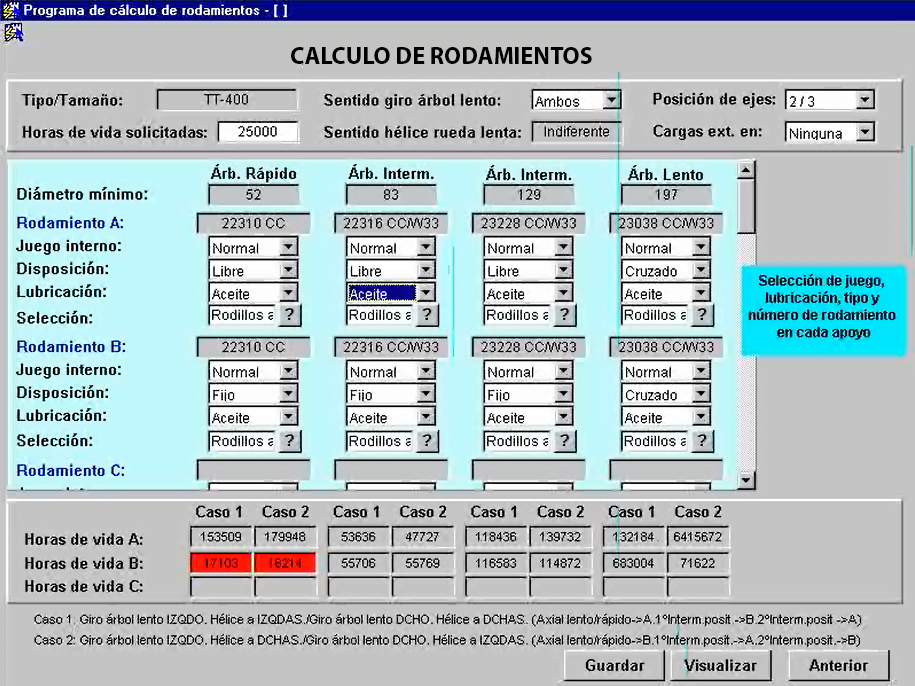

Bearings Calculation Module

From the input data and once the gear calculations have been completed, this module will carry out the calculations for the bearings of all the gearbox shafts and the results will be stored in the database.

Template Display Module

It is the starting point of the application, since it is the module where the gearbox at hand data is input from. The input data include general information as well as precise data to carry out the subsequent calculations. It is in this module where the customer particular technical specifications are introduced.

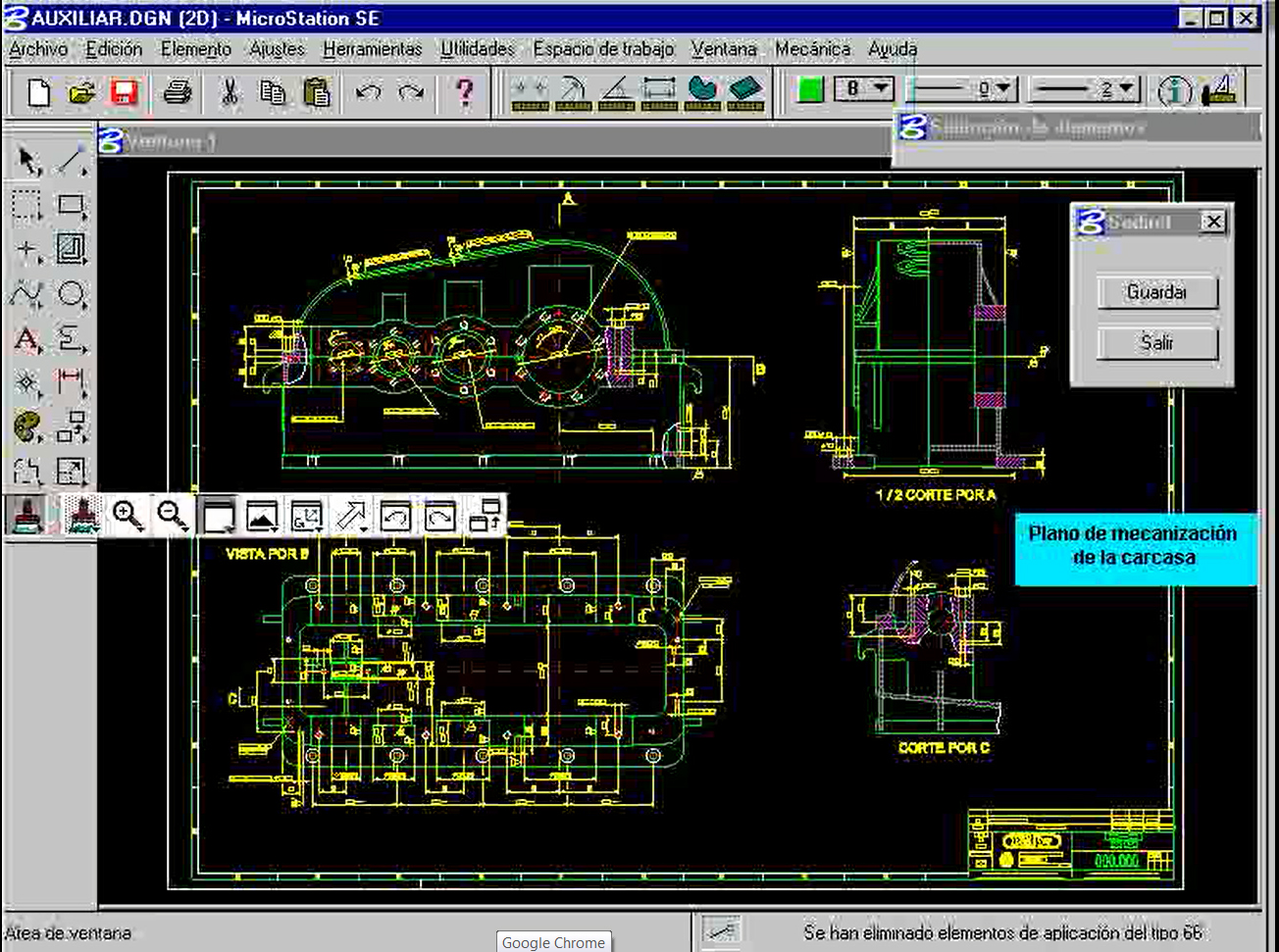

Housing Dimensional Drawing Display Module

The same way as with the previous module, this one enables displaying in the CAD MicroStation system the resulting dimensions of the calculations of the gears and bearings, stored in the database.

Component Dimensional Drawing Display Module

This module obtains from CAD MicroStation the dimensional plans of the gearbox components: shafts, wheels, caps and spacers.

Reporting Module

This module generates the technical reports of a gearbox from the calculation information stored in the database. The reports are generated in Microsoft Word format.