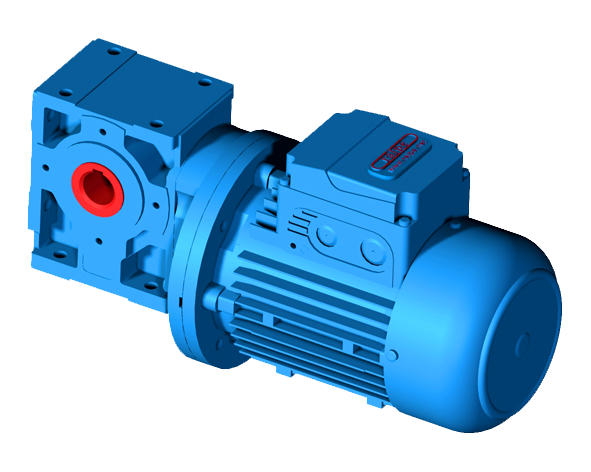

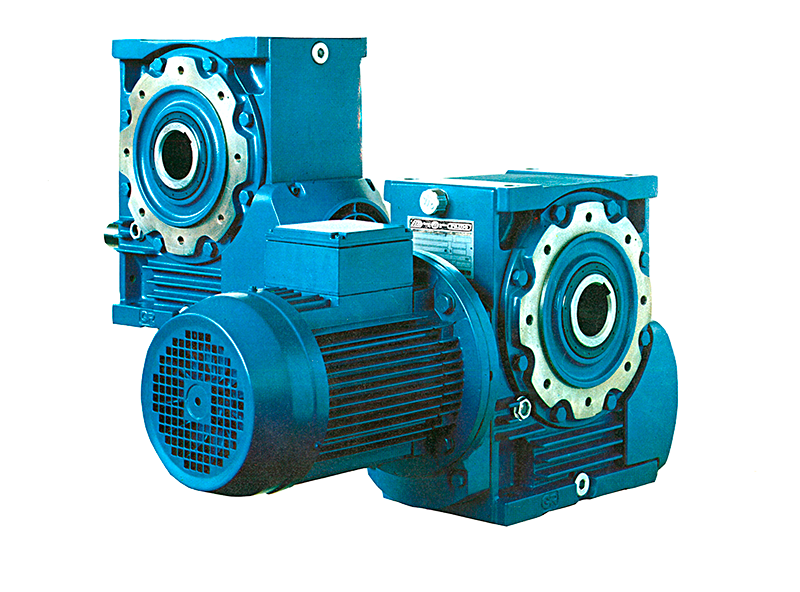

RALPE Worm Gearboxes

This range of speed reducers is based on a modern analytical conception of each of its components, on mechanization carried out by state-of-the-art equipment and advanced control systems applied to all manufacturing processes, providing high reliability.

The range of worm gearboxes is produced according to International Standards, with 10 sizes based on the distance between the centres of the exit train of 32, 40, 50, 63, 80, 100, 125, 160, 200 and 250.

This line of mechanisms, thanks to its design configuration, can be assembled with gearboxes and gear motors of different RALPE series, achieving groups of high ratios that enable the transmission of high nominal pars and maximums the worm gearbox achieves at low speed.

Technical Specifications

10 sizes based on the distance between the centres of the exit train of 32, 40, 50, 63, 80, 100, 125, 160, 200 and 250.

Attributes

Mounting- Universal standard mounting with upper and lower legs integrated in the housing and B14-type flange.

Other mounting options:

Female B5-type flanged housing, with the option of mounting on both ends of the exit axle .

Pendular mounting on the hollow shaft and reaction arm with adjustable tensor.

Exit axle- Hollow exit shaft made with standard keyway and integrated in the worm gears, slots for elastic rings in sizes 100… 250.

Solid exit shaft with simple end mounted right-hand or left-hand.

Solid exit shaft with double end.

Housing-Housing manufactured in high-quality grey cast iron, with high capacity for lubricant and ribbed inside cross-braces.

Gears-Worm wheel built in steel, mechanised with involutes profile, case-hardened/tempered, rectified and superfinishing.

Worm gear built in phosphor bronze and integrated in the exit hollow shaft.

Helical spur gear made of steel hardened / tempered and with rectified profile

Ventilation- Sizes 100… 250 equip the system with forced ventilation by a turbine mounted over a double-exit worm gear, this exit being useable removing the central protection.

Lubrication-The lubrication is done with oil bath. Sizes 32… 80 are delivered with long-lasting synthetic oil; sizes 100… 250 are equipped with filling caps with a venting valve, draining cap and level, to use either synthetic or mineral oil

Other mounting options:

Female B5-type flanged housing, with the option of mounting on both ends of the exit axle .

Pendular mounting on the hollow shaft and reaction arm with adjustable tensor.

Exit axle- Hollow exit shaft made with standard keyway and integrated in the worm gears, slots for elastic rings in sizes 100… 250.

Solid exit shaft with simple end mounted right-hand or left-hand.

Solid exit shaft with double end.

Housing-Housing manufactured in high-quality grey cast iron, with high capacity for lubricant and ribbed inside cross-braces.

Gears-Worm wheel built in steel, mechanised with involutes profile, case-hardened/tempered, rectified and superfinishing.

Worm gear built in phosphor bronze and integrated in the exit hollow shaft.

Helical spur gear made of steel hardened / tempered and with rectified profile

Ventilation- Sizes 100… 250 equip the system with forced ventilation by a turbine mounted over a double-exit worm gear, this exit being useable removing the central protection.

Lubrication-The lubrication is done with oil bath. Sizes 32… 80 are delivered with long-lasting synthetic oil; sizes 100… 250 are equipped with filling caps with a venting valve, draining cap and level, to use either synthetic or mineral oil